How Back-to-Back Fulfillment Works

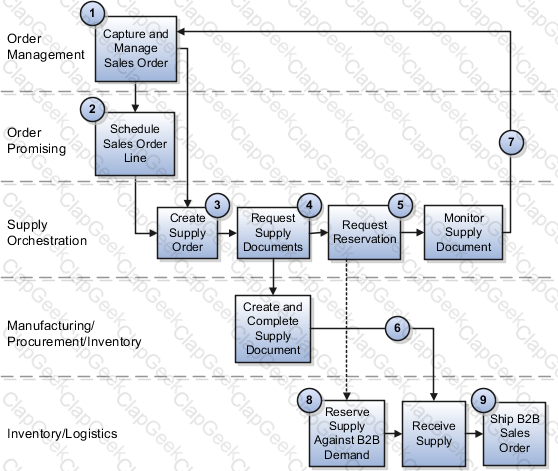

The back-to-back process flow is one in which specific sales order demand triggers supply creation and a link is established between the sales order and the supply.

An organization procures goods from an internal or external supplier or source to a specific warehouse from where you can combine those goods with others to create a single shipment to the customer.

Back-to-back supply processes are similar to regular supply processes that deliver supply to a warehouse except for one difference; the back-to-back supply is always reserved to an order management fulfillment line.

At a high level, you can think of back-to-back fulfillment as a three-step process:

1.Creation of a customer sales order (source of demand).

2.Creation and fulfillment of supply document (source of supply) to the fulfillment warehouse.

3.Shipment of sales order from the fulfillment warehouse to the customer.

However, the back-to-back flow is truly a highly integrated process flow involving several Oracle Fusion Cloud applications. The following figure shows the back-to-back process flow in detail. An explanation for each number follows the figure.

Set Up Back-to-Back Transfer Flow

The topic explains what you need to do for setting up back-to-back transfer flow.

In the Oracle Product Information Management, ensure that the Item is Back-to-Back enabled.

In Oracle Global Order Promising:

1.Set up a global sourcing rule with Type as Transfer from. Set the organization as the organization requesting the transfer (example, Warehouse 1).

2.Set up a local sourcing rule for the organization (in this example, Warehouse 1) Type as Transfer from, from the organization that has the stock from which the transfer will take place (example, Warehouse 2).

3.Set up an ATP rule with the Promising Mode as Supply chain availability search.

4.Ensure that the Supply chain availability search attributes are enabled according to your requirements. For example, you might want the application to search components and resources to include on-hand or in-transit Supply Types or fulfillment lines Demand Types.

5.Set the ATP Rule Assignment as required.

6.Set the sourcing assignments for the sourcing rules that you defined in steps 1 and 2.

7.Ensure that the assignment level used for the global sourcing rule doesn't include any Organization.

8.Refresh and restart the Order Promising Server for ATP Rules and Sourcing.

With this setup:

•The global rule is used to source the item from Warehouse 1 if there is stock available to reserve.

•If there's no stock on hand, Global Order Promising uses the local rule to transfer the item from Warehouse 2 to Warehouse 1.

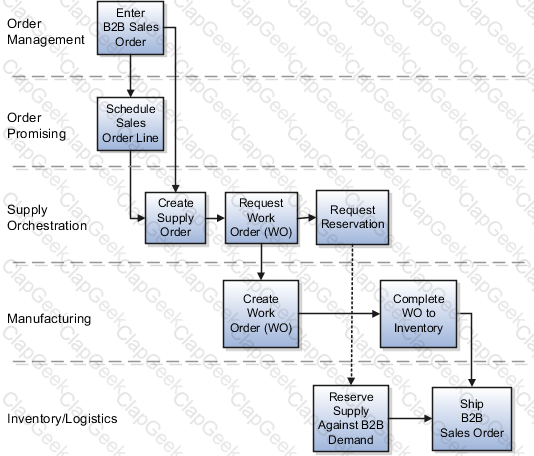

Back-to-Back Supply Creation Make Flow

The supply document for a back-to-back make flow is a work order. As soon as the work order is created in Oracle Fusion Cloud Manufacturing, it's tied to the back-to-back sales order in the form of a reservation in inventory. The work order goes through the regular production process and the work order completion transaction issues finished goods to inventory.

Note: Back-to-back flow is currently supported for only discrete manufacturing.

The following figure shows the back-to-back supply creation make flow.

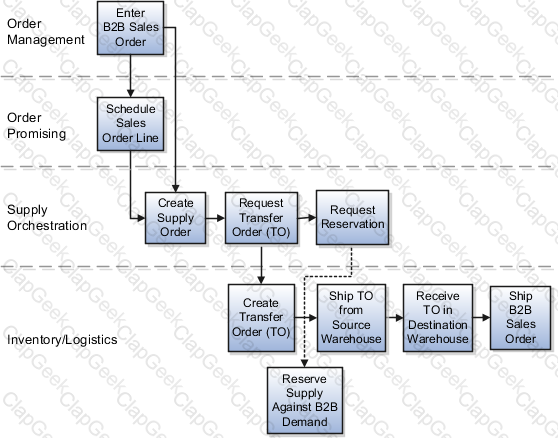

Back-to-Back Supply Creation Transfer Flow

The supply document for a back-to-back transfer flow is a transfer order. The transfer order is created in inventory and reserved against the back-to-back sales order. When the transfer order is ready to be fulfilled, an interorganization shipment moves goods from the source organization to the destination organization. An interorganization receipt in the destination organization (which is also the fulfillment warehouse on the back-to-back sales order) creates on hand to fulfill the sales order.

The following figure shows the back-to-back supply creation transfer flow.

In your shipment integration between inventory cloud and the 3PL system, some shipment confirmation messages have errored.

How do you manage these pending transactions?

Your customer has created a Cycle Count by Item category. The Generate Count Schedules and Generate Count Sequences jobs have completed successfully. However, count schedules and count sequences are not created.

What could be the reason?

Which three sort criteria are available to pick material for a movement request?

Steve, your warehouse manager, created a lot for an item by mistake. He is unable to disable this lot from the Manage Lots task.What could be the reason?

While performing a physical inventory count, you find that tags have not been generated for some of the items.

What action is recommended?

Your supplier has reduced the supply quantity from 100 to 80 for a supply order with a requested quantity of 100. Supply Chain Orchestration is unable to find an alternative source of supply to meet this demand.

What will this supply line be grouped under?